Assembly

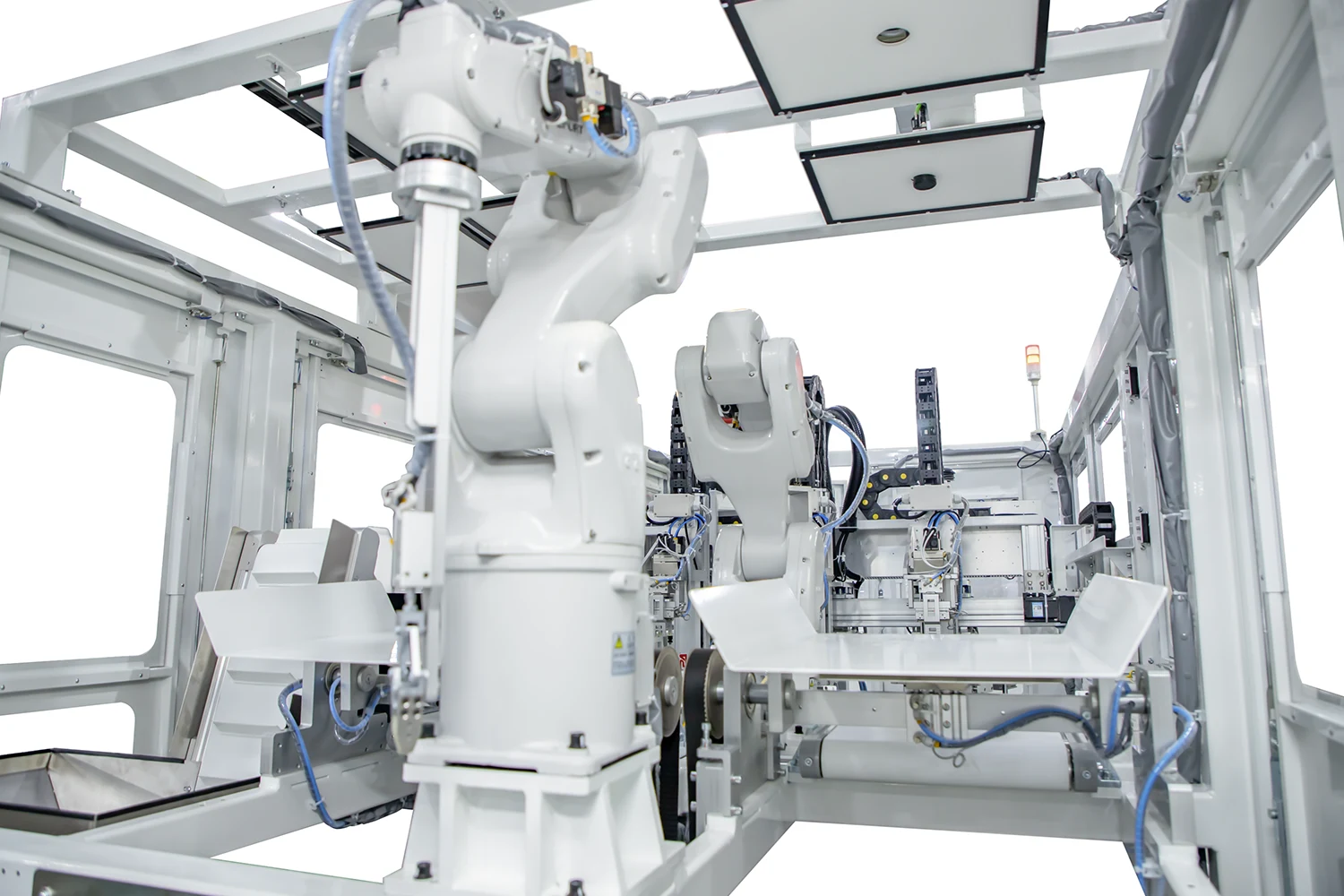

Automated Junction Box and capping Installation System for Multi-Specification PV Modules

Efficient, precise, and adaptable – Our equipment production line is designed to meet the demands of modern manufacturing. Whether your PV modules are full-cell, half-cut, or dual-glass modules, or whether they require U-type or O-type split junction boxes (≤3 junction boxes parallel to the short edge, centered on the module,with ≤3 boxes), our systems ensure accurate feeding, positioning, and assembly of workpieces.Through collaborative equipment production line , we deliver optimized technical solutions tailored to your needs—or, when required, design entirely new equipment internally to meet specialized requirements.Our equipment delivers unparalleled reliability, speed, and efficiency in high-speed junction box handling for PV modules—including precision pick-and-place, lead wire alignment correction, fully automated junction box installation, and capping. Optimize your production flow and boost cycle time with our cutting-edge automation solution

We have extensive experience in the PV equipment industry. Our equipment can be assembled correctly and effectively, regardless of whether your PV modules are full-cell, half-cut, or dual-glass modules, or whether they require U-type or O-type split junction boxes (≤3 junction boxes parallel to the short edge, centered on the module,with ≤3 boxes).

Our experienced engineering and technical team adopts a collaborative approach for every project. If we are unable to find suitable components or systems for integration, we will design and manufacture internally to meet your exact specifications. This ensures that every detail of the system is optimized for your production needs. We tailor the best equipment, software, and technology for your specific application. Our solution is efficient and reliable, and the results have been verified to improve your manufacturing speed, productivity, and overall profitability.

Functions of the assembly equipment

- Automatic module alignment

- Robotic Pick-and-Place

- Module installation

- Vision inspection

- Vision-guided positioning

- Mechanical Alignment Correction

- Vacuum suction handling

- Vacuum integrity test

- System integration

- Vision-guided Assembly

Equipment example

J-Box Installing Machine