Welding

High-Precision Automated Dispensing Solutions — Enabling Efficient and Reliable Encapsulation of PV Modules.

Our professional technical team provides comprehensive customized dispensing solutions for PV production lines, encompassing core equipment, precision valves, and intelligent control software. We are committed to achieving precise adhesive control, ensuring consistent bead width and clean start/stop points to guarantee long-term sealing between backsheets and junction boxes while optimizing cost efficiency.

We deliver robust dispensing systems that integrate seamlessly into automated production lines, enabling real-time monitoring of production data and quality control. Our solutions support unmanned operations and enhance overall productivity. We offer full life-cycle services—from process validation and equipment integration to installation, commissioning, training, and maintenance—ensuring reliable and continuous performance.

Functions of Dispensing

- Our Core Technologies:

- High Repeat Positioning Accuracy (±0.1mm)

- Precise Glue Volume Control

- Vision Guidance and Inspection

- MES Integration for Data Traceability and Flexible Production

- Junction Box Bottom Sealing

- Dispensing for Shingled Module Strings

- Busbar Fixation and Insulation Protection

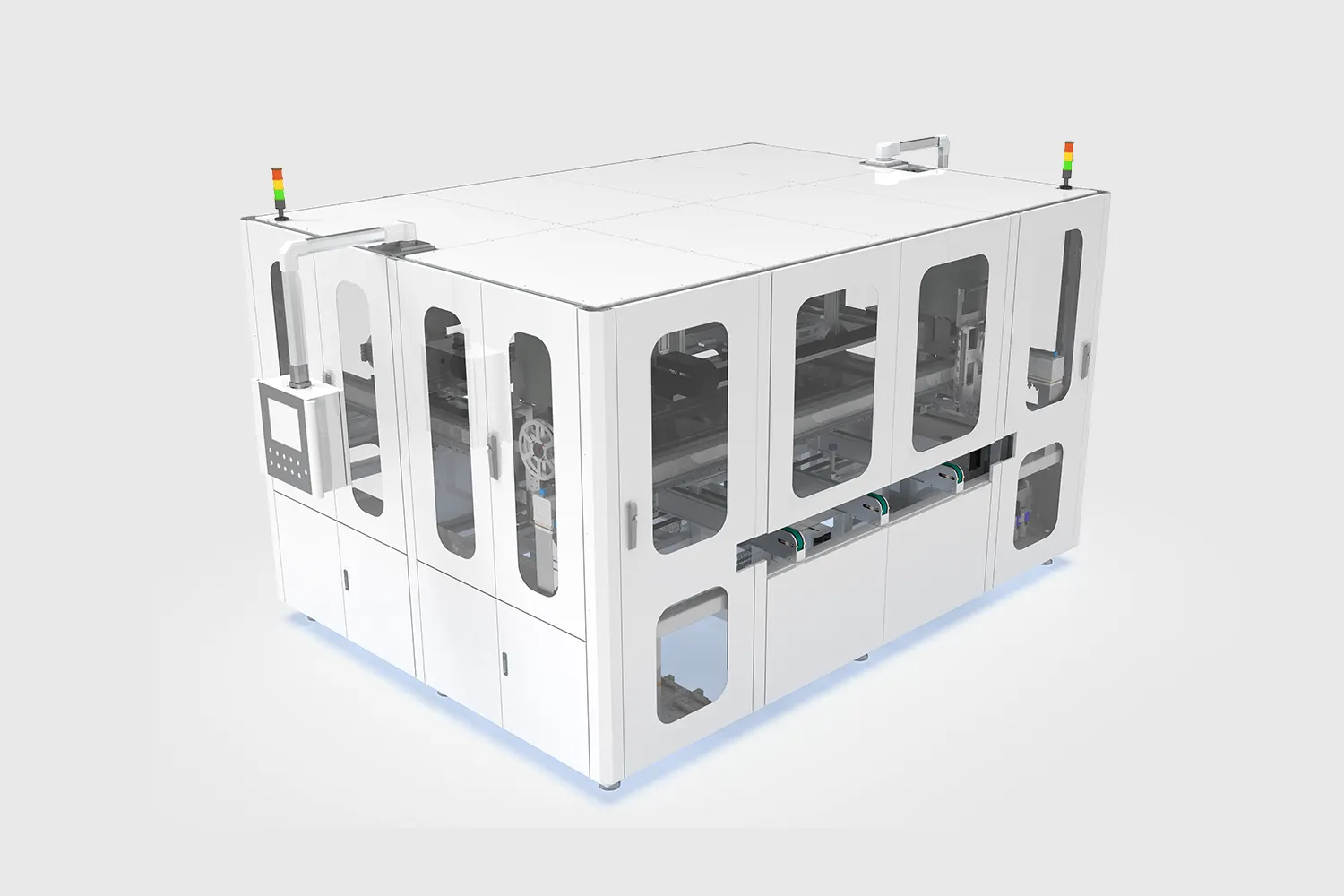

Equipment example

Backside Glue Dispenser

Fully automated adhesive application system designed for precision junction box mounting on PV module backsheets. Delivers high-speed operation with micron-level accuracy, integrated auto-calibration, and intelligent pattern recognition for seamless format changeovers.