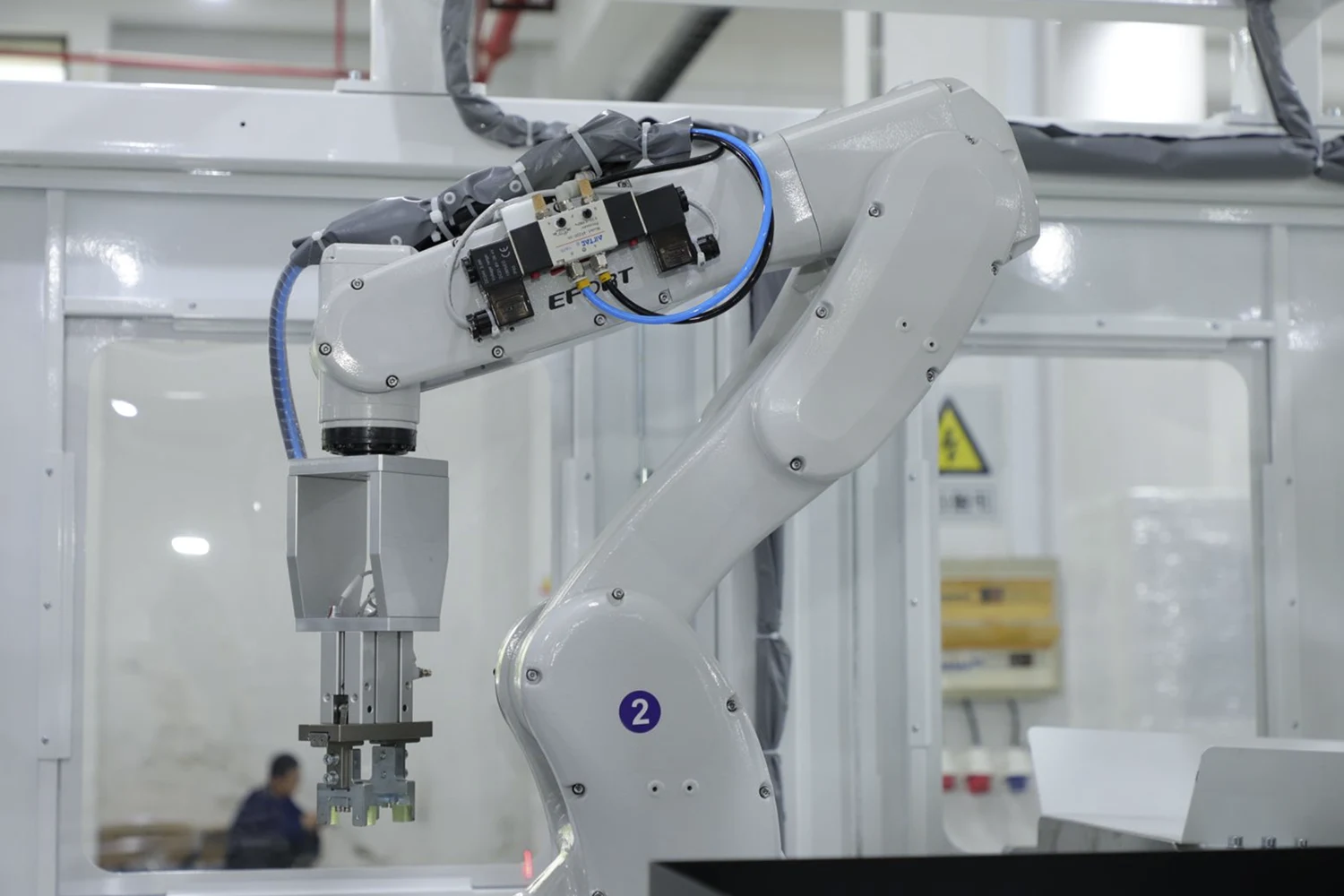

Robotic Integration

Advanced machines with integrated loading, unloading, and installation functions.

Our company leverages advanced robotic automation workcells to optimize manufacturing efficiency, enhance product precision, and improve process reliability. With specialized expertise in robotic applications for the photovoltaic manufacturing industry, we develop tailor-made robotic automation solutions designed to meet the unique requirements of solar production processes.

Robot functions

We have extensive expertise in the photovoltaic equipment industry. Whether dealing with grid-tie full-cut modules, half-cut modules, or double-glass modules, our U-shaped or O-shaped panel wiring harnesses – specifically designed for parallel three-way junction boxes at module midpoints with no more than three units – can be accurately and efficiently assembled using our specialized equipment.

Our seasoned engineering team collaborates closely on every project. When components or systems cannot be sourced for integration, we design and manufacture them in-house to precisely meet your specifications. This ensures every system detail is optimized for your production needs. We tailor optimal equipment, software, and technologies specifically for your application. Our proven solutions enhance manufacturing speed, boost productivity, and strengthen overall profitability through efficient and reliable results.

Robot functions

Assembly

Flexible loading/unloading

Weld

Distribution

Visual guidance

Collaborative robot integration

Material handling

Pick up and place

Advantages of robots

Improve productivity

High accuracy positioning

Product quality is stable

Efficient

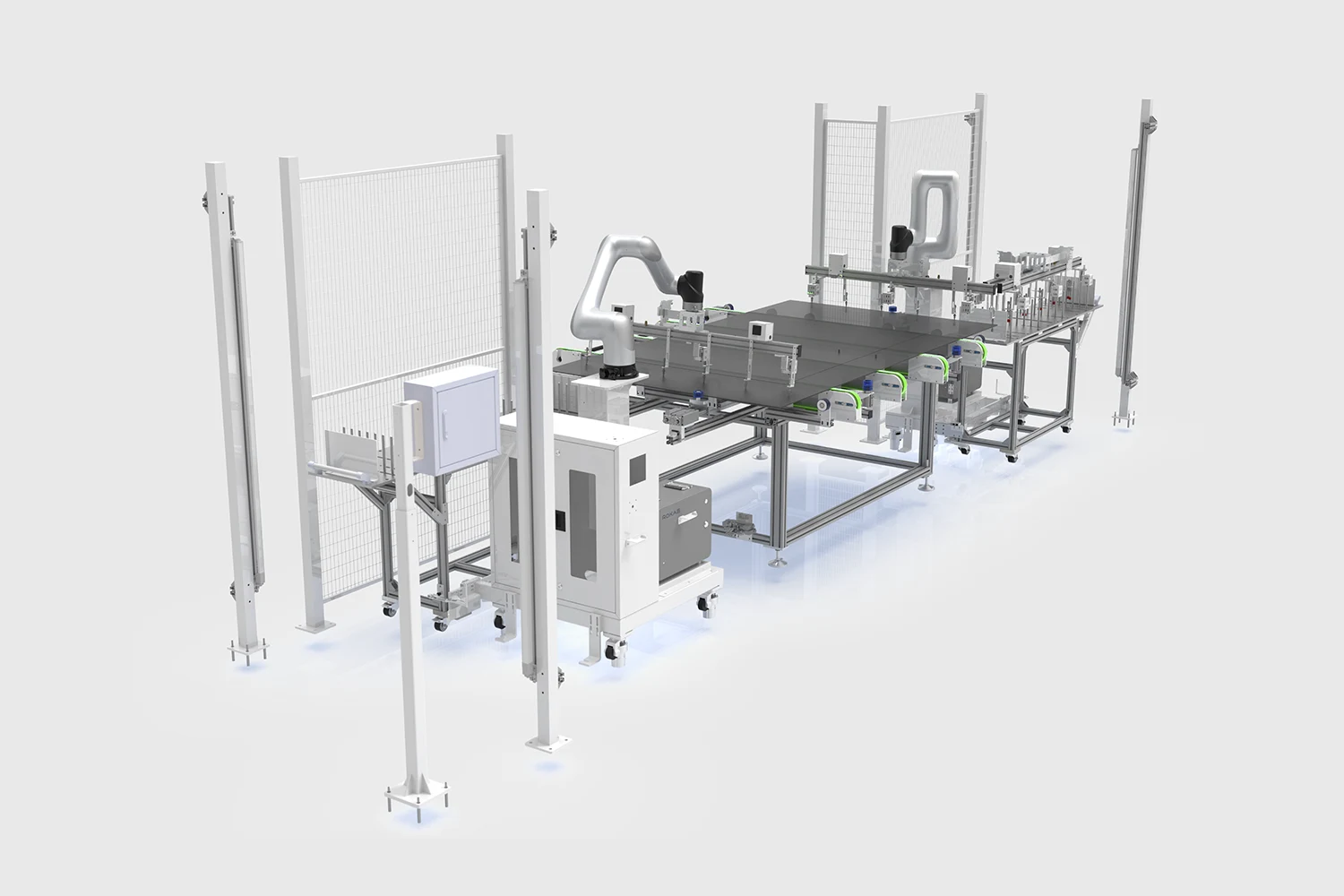

Equipment example

EVA Laying Module Equipment

The robotic system automatically places pre-cut EVA patches onto ribbon locations. An integrated vision system performs imaging inspection after placement to verify accuracy, while an automatic deviation correction function ensures precise positioning. The equipment delivers high-speed, stable operation with a compact footprint and user-friendly, flexible controls.