Welding

Professional Junction Box Welding Technology: Delivering a Robust and Reliable "Heart" Connection for PV Modules

In PV module manufacturing, junction box welding quality directly impacts overall performance, operational safety, and product lifespan. Our integrated solutions cover the entire process, including precision welding equipment, fully automated lines, and seamless technical support.

Our Core Technologies:

Leading-Edge Welding Processes:

Utilizing advanced techniques such as [laser welding / thermal compression welding / soldering iron welding / electromagnetic welding], we achieve perfect connections—whether contact or non-contact—with low stress and high strength.

Intelligent Vision Systems:

High-precision CCD cameras automatically identify weld points and compensate for deviations, ensuring every connection is precise and accurate.

Data-Driven Process Control:

Full traceability of production data provides a solid foundation for quality analysis and continuous improvement.

High Compatibility & Flexibility:

Our equipment supports quick changeovers for various junction box and busbar types, minimizing downtime and adapting seamlessly to high-mix, low-volume production trends.

Make Reliable Connections Your Competitive Advantage

A flawless weld is a promise of 25 years of efficient power generation. Choosing us means choosing peace of mind and unwavering reliability.

Functions of Welding

- High-Rigidity Frame

- Multi-Axis Motion System

- Dedicated Clamping Fixture

- Vision Positioning & Inspection System

- Automated Solder Wire Feeding Unit

- PLC + Industrial PC Control

- Parametric Programming

- Data Traceability & MES Integration

- Real-Time Welding Process Monitoring

- Smoke Extraction System

- Fault Diagnosis & Alarm System

A critical process that eliminates false connections, reduces energy loss, and enhances the overall lifespan and efficiency of PV modules.

Over the 25-year lifecycle of a solar power plant, the reliability of junction box connections directly determines a module’s power output and operational safety. Traditional plug-in and crimping methods are susceptible to vibration, thermal cycling, and environmental factors—often leading to increased contact resistance, overheating, and failure.

Our professional soldering iron welding technology creates molecular-level metallurgical bonds between diodes, cables, and busbars, protecting your investment down to the smallest detail.

We introduce precision welding with full-process control, delivering military-grade connection reliability for PV junction boxes.

Defining Reliability on a Micron Scale

As the pursuit of extreme longevity and efficiency in photovoltaic modules continues, traditional soldering methods have reached their limits. Thermo-compression bonding offers a breakthrough approach: using precisely controlled heat and pressure to achieve solid-state diffusion bonding at the atomic level—without solder.

This process eliminates the root causes of failure such as cold joints, tin whiskers, and corrosion, delivering the ultimate connection solution for next-generation high-efficiency modules.

We provide complete integrated solutions—including high-precision bonding equipment, custom-designed bonding heads, seamless production line integration, and full-process data traceability—all designed to bring industrial-grade reliability and precision to your manufacturing process.

Photon-Powered, Connection Revolution: Laser Welding for PV Junction Boxes Enters the Era of Non-Contact Joining

As PV modules enter the “Age of Micron Precision,” mechanical contact and thermal stress have become the enemies of reliability. To overcome limitations inherent in traditional soldering and thermo-compression bonding—such as thermal damage, tool wear, and process drift caused by pressure fluctuations—we have advanced laser welding technology for junction box applications.

This precision technique, adopted from high-end manufacturing, utilizes a non-contact, high-energy-density laser beam to achieve instant metallurgical bonding between junction boxes and busbars. The result? The complete elimination of cold joints, heat affect zones, and residual stress.

Laser welding delivers the ultimate connection solution for ultra-high-power modules, offering unmatched precision and quality for the next generation of solar technology.

No Heat. No Pressure. A New Paradigm for Energy-Based Joining.

In the pursuit of higher production rates and absolute reliability, the limitations of thermo-compression bonding (stress) and laser welding (cost) have become bottlenecks. To overcome these drawbacks, we introduce Magnetic Pulse Welding (MPW)—a groundbreaking non-thermal welding technology tailored for next-generation high-efficiency PV modules.

MPW utilizes a high-intensity pulsed magnetic field to generate powerful electromagnetic forces, creating a solid-state metallurgical bond between materials in microseconds. The entire process requires no heat input, produces no heat-affected zone, and ensures truly non-destructive welding—fully protecting cell integrity and encapsulation materials. With significantly increased cycle times, MPW represents the future of cold-joining technology.

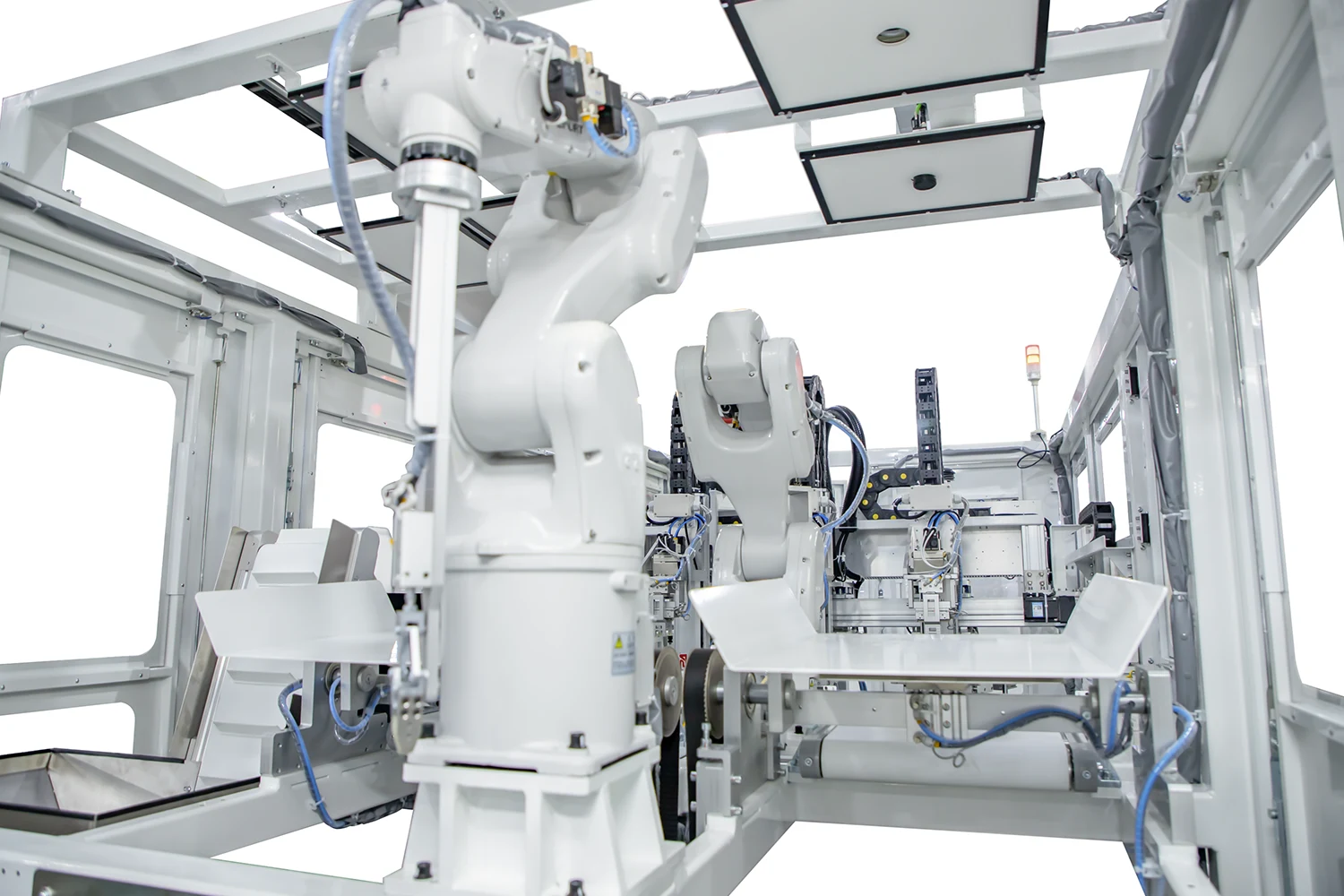

Equipment example

J-Box Soldering Machine

Automatically dresses and thermocompression-bonds lead wires within junction boxes.The system automatically interfaces with upstream/downstream processes, utilizing an XYZ servo gantry with vision-servo positioning for precise alignment, and incorporates intelligent welding quality verification. Compatible with diverse PV modules, supports rapid changeover, features liquid-cooled design, and delivers highly efficient, stable operation.