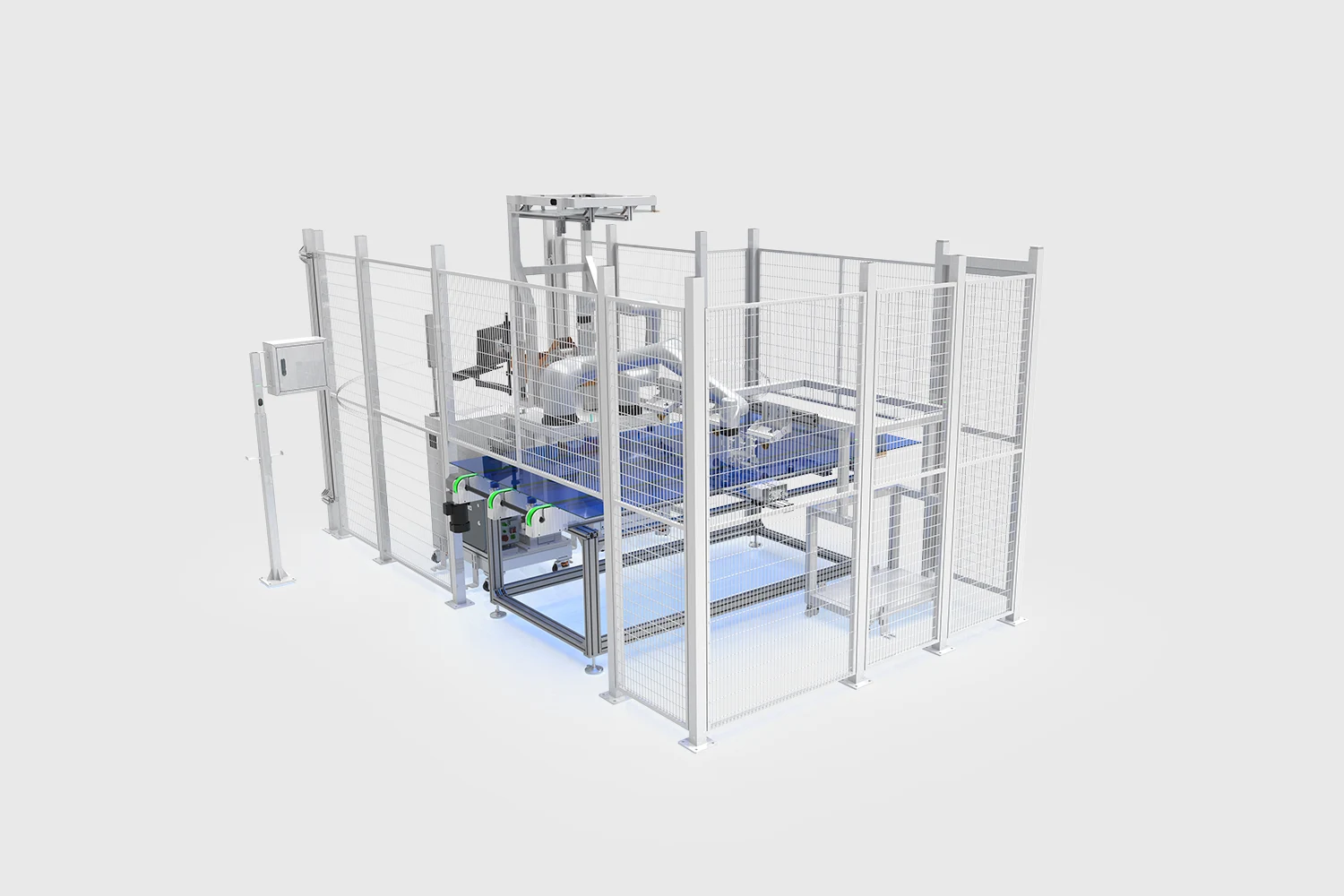

The system utilizes a vibratory bowl feeder for disordered feeding and a robotic unit for automated installation, enabling automatic high-temperature fabric placement and ribbon bending operations. Equipped with a vision positioning module that works in coordination with the robotic system, the machine achieves high positioning accuracy and ensures fast, stable installation. The equipment operates at high speed with exceptional stability, featuring a compact layout and user-friendly, flexible operation.

| Applicable edition | 1650-2520(mm);990-1450(mm) |

| Cycle Time | 14s |

| Source | Single-phase AC220V, 50Hz,3.0kVA |

| Gas source | 0.4-0.6(MPa);压缩空气/Compressed Air:0.5m³/min |

| Noise | ≤60dB |

| Net Weight | 1500kg |

| Equipment Size(L×W×H) | 4400*2470*2430mm |

| Compatible with incoming material specifications | 1. Apply U-shaped opening high temperature cloth, the opening width>10mm

2. Manual material removal is required, and high temperature cloth should be free from contamination, residual glue and deformation |