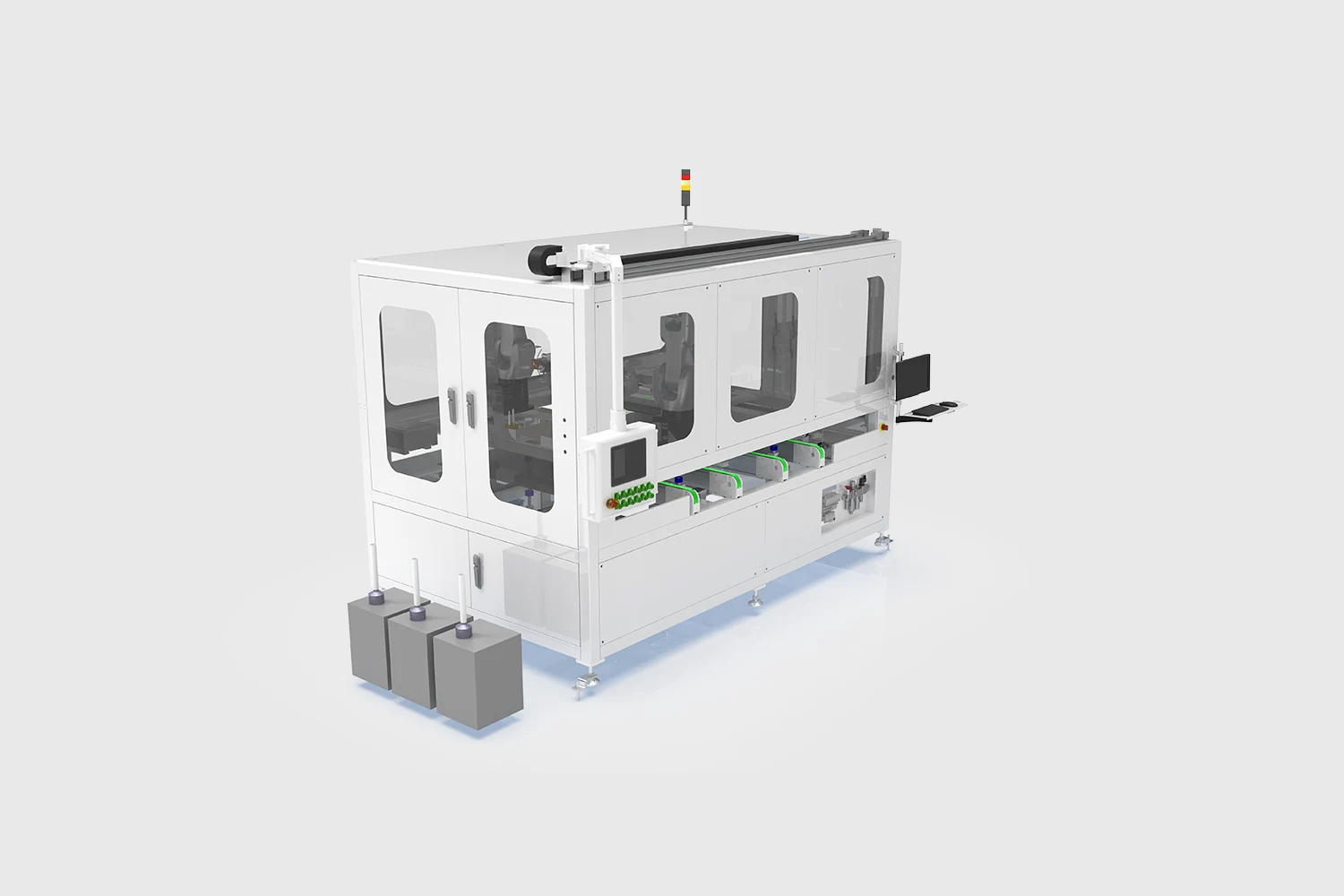

Used for automatically flattening and soldering internal leads of junction boxes with an iron. The equipment automatically connects upstream and downstream processes. The XYZ gantry, combined with a visual servo system, ensures precise positioning and intelligent inspection of soldering quality. Compatible with various components and supports quick changeover. Designed with water cooling for efficient and stable operation.

| Applicable edition | L:1650-2520(mm);W:990-1450(mm) |

| Cycle Time | 16s(2) |

| Source | AC 3 phase, 380V/N/PE, 50Hz, 12kVA |

| Gas source | 0.4-0.6(MPa);Compressed Air:0.4m³/min |

| Noise | ≤72dB |

| Net Weight | 2000kg |

| Equipment Size(L×W×H) | / |

| Compatible incoming material specification | 1. The diameter of tin wire is 1.0mm

2. Tin at the bottom of the junction box 4mm, 8mm and 1mm (tinned copper at the bottom) |

| Welding tension | ≥30N |

| Temperature control accuracy | ±5 |

| Welding positioning accuracy | ±0.5mm |