Laminate Frame Return Line adopts a short-edge vertical conveying method, allowing for ±5mm width variation and ±100mm length variation of the lamination frame without mechanical adjustment, significantly reducing changeover time.

Additionally, the system integrates a frame placement detection function, utilizing a vision system to monitor the spacing between the lamination frame and the laminated module, ensuring proper alignment and minimizing the risk of cell cracking. This enhances process quality control and improves production stability.

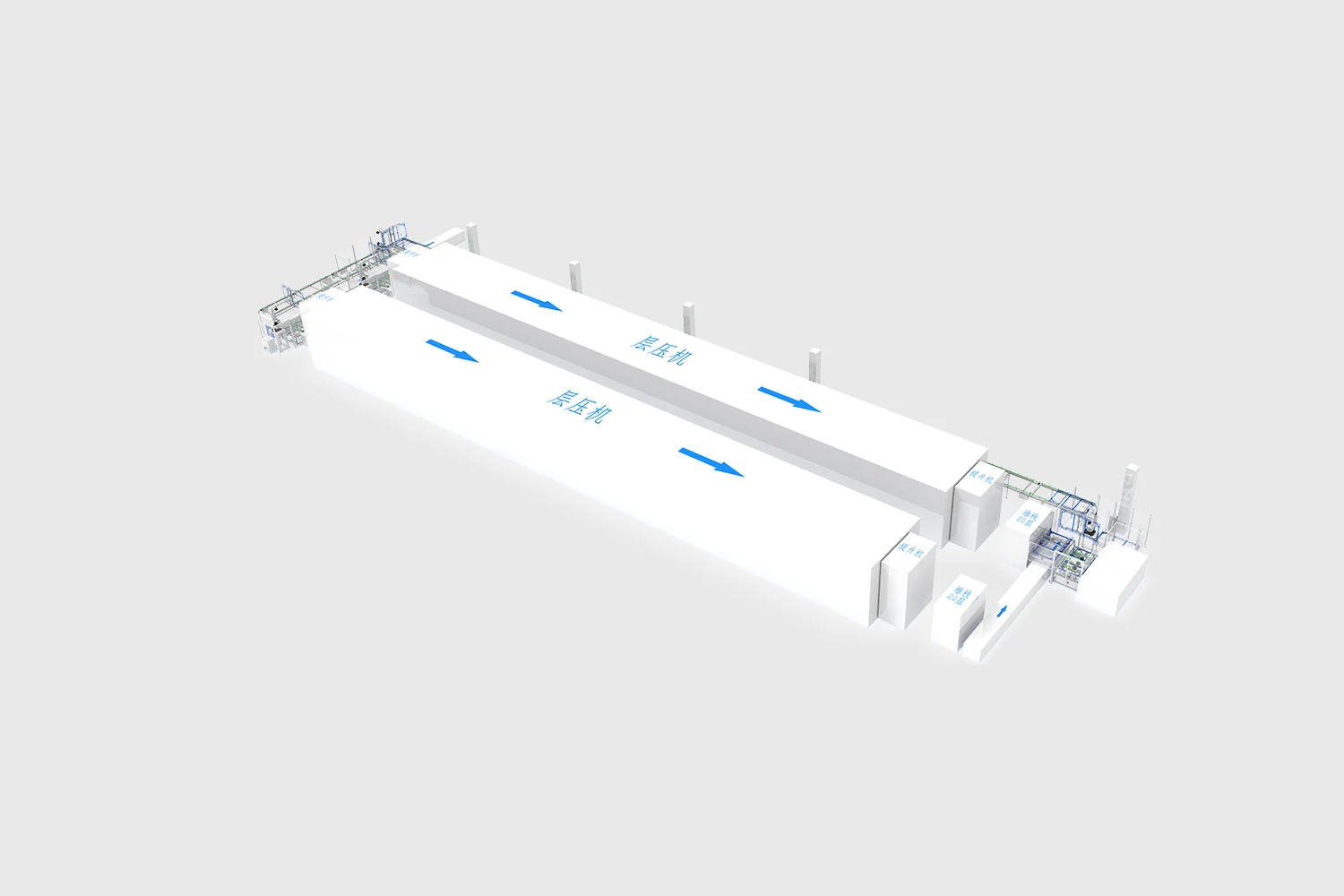

The system achieves fully unmanned operation in the lamination frame recycling process.

| Applicable edition | L:1650-2520(mm);W:990-1450(mm) |

| Cycle Time | 12s |

| Source | AC 3 phase, 380V/N/PE, 50Hz,18kVA(Feeding) |

| AC 3 phase, 380V/N/PE, 50Hz,12kVA(Blanking) | |

| Gas source | 0.4-0.6(MPa);Compressed Air:1m³/min(Feeding) |

| 0.4-0.6(MPa);Compressed Air:0.7m³/min(Blanking) | |

| Noise | ≤80dB |